The 2024 German ACHEMA Exhibition, a century-old process industry event that has attracted worldwide attention, opened grandly at the Frankfurt International Exhibition Center in Germany from June 10th to 14t,. Zhejiang Yaguang Technology Co., Ltd. brought new energy lithium batteries, fine chemicals, pharmaceuticals, environmental protection and other industry solutions to the same stage with international peers to jointly discuss the innovation and development of the global chemical industry.

API complete production line solution with " The Agitated Nutsche Filter Dryer" as core product

Yaguang Co., Ltd. has been deeply involved in the pharmaceutical machinery industry for more than 20 years. It is the exclusive drafting unit of China's national industry standards for rubber stopper and aluminum cap cleaning machines and filter washing and drying machines. At this exhibition, Yaguang Co. , Ltd. brought a more innovative, efficient and energy-saving API raw material production line solution with the above equipment as the core on the international stage, which won wide attention and high praise from the audience. Yaguang API production line system is safe, reliable and stable, suitable for large and small batch production, suitable for innovative drugs and high-end generic drugs. The entire production line can realize multi-variety and multi-process automated production through program formula setting, and can realize online segmented CIP&SIP, realizing fully closed and aseptic production of the system.

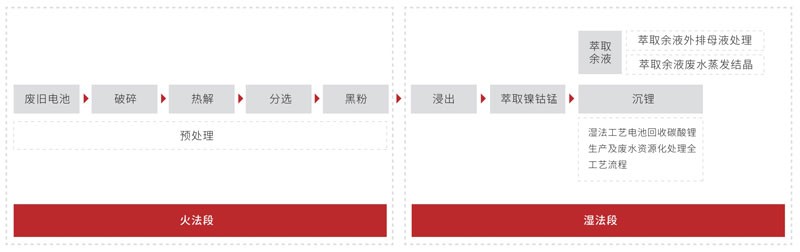

Power battery recycling pyrometallurgical and hydrometallurgical process solutions

In the field of lithium-ion new energy, Yaguang Co., Ltd. and its subsidiaries have been continuously optimizing and innovating the solutions for the pyrometallurgical, hydrometallurgical and powder process engineering of positive and negative electrode materials for many years, and have accumulated rich cases and experience in process design, product quality, upstream and downstream supporting processes, and project execution management. At this event, the full-process solution for power battery recycling brought by Yaguang Co., Ltd. attracted many international visitors come and consulting.

MVR steam compressor and system integration

Hebei Leheng Energy Saving Equipment Co. Ltd., as a subsidiary of Yaguang Co., Ltd., one of the few top evaporator manufacturers in China that has mastered the technology of steam power equipment. Based on MVR steam power equipment technology, after years of continuous research and development and optimization, Leheng can now provide multiple series of steam compressors. The maximum evaporation capacity of the system can reach 100T/h, We can achieve stable and efficient operation under different working conditions in different industries. Leheng Energy Saving has advanced customized design capabilities, pneumatic design capabilities, and processing capabilities in power equipment, and we can provide highly personalized energy-saving equipment solutions based on the specific needs of customers. At the same time, Leheng equipment can be used as the core to integrate external equipment to provide customers with an overall planning of the process system.

During this exhibition, Yaguang Co., Ltd. demonstrated our product technology and outstanding strength to exhibitors from all over the world. In the future, Yaguang Co., Ltd. will continue to explore the international market and strive to provide customers with "honest, fair, high-quality and efficient" services. We look forward to working hand in hand with more international partners to demonstrate the elegance of Made in China with excellent products and services and contribute Chinese strength to global industrial development!