Vapour compression distillation is a high efficiency method to produce water for injection (WFI), the WFI produced by AGT vapor compression distillation system can meets the most strict pharmaceutical standard and in accordance with all recognized pharmacopoeias.

Endotoxins<0.01EU/ml;

Conductivity<0.3μm/cm @25℃

Low evaporation temperature, low risk of producing red rust;

Low OPEX benifits from Maglev steam compressor

Equipped with real-time energy consumption monitoring and analysis function

Skid-mounted design, plug-in and play

No lubricating oil and cooling water

Lelink IIoT ready

Atmospheric pressure operation;

No high-temperature external drainage, no need for cooling water

Comprehensive safety chain protection

Maglev compressor, stable operation, low maintenance requirements

Rising film evaporation technology, stable and efficient

Maglev (Magnetic levitation) is a cutting-edge bearing technology that has been widly used in air compressor and other rotating equipment fields, AGT and it's subsidiary Leheng develped the maglev steam compressor together according to the pharmaceuiticle guidlines. Mechanical vapor compression (MVC) has been widly used in various applications like MVR evaporator, heat pump assisted distillation. The maglev steam compressor featuring friction free, oil free, and cooling water free, that means the compressor has higher effeciency and lower consumption.

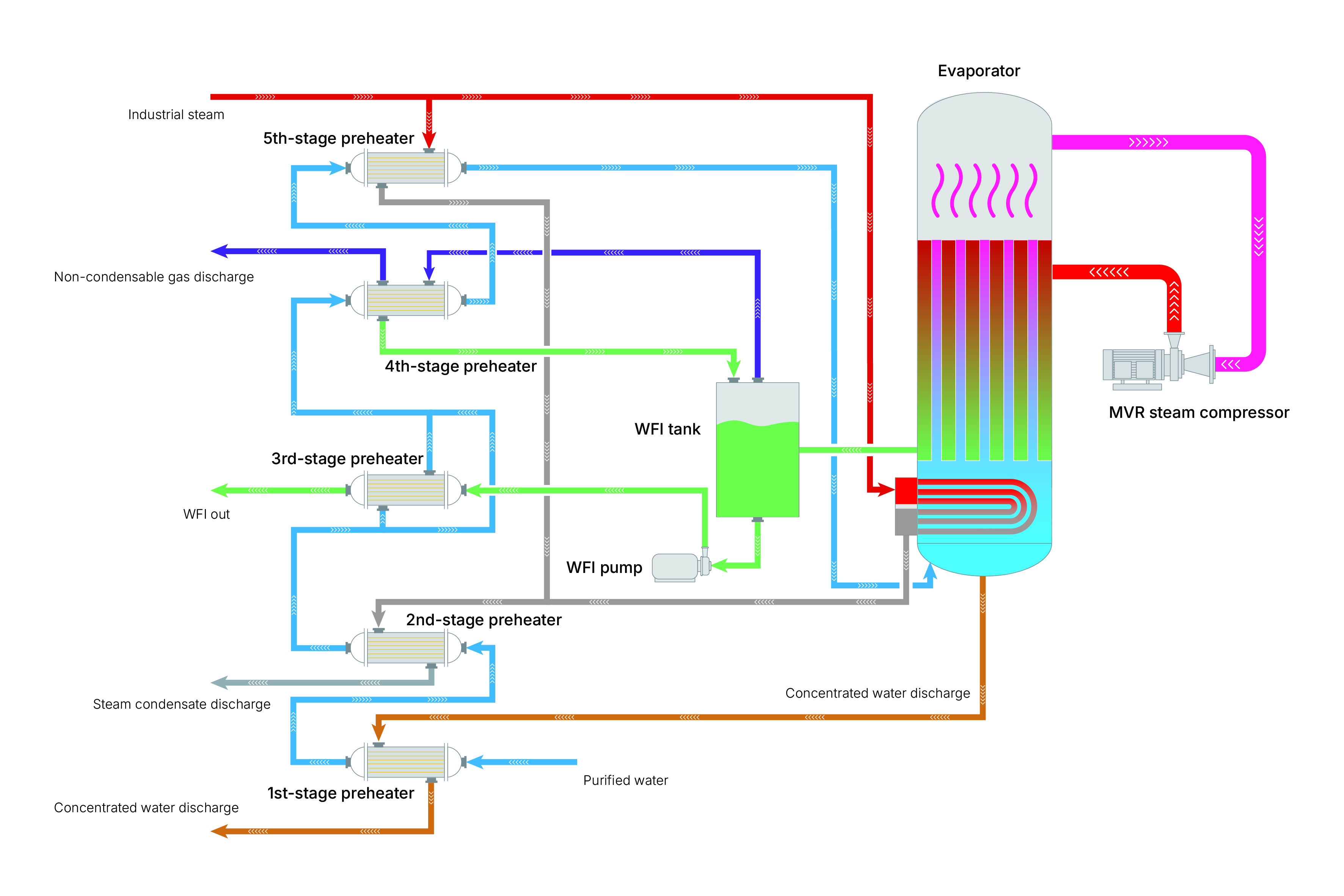

The distiller employs a 5-stage pre-heating system, which can maximizing the use of residual heat within the system, and ensuring no high-temperature water is produced. Pharma grade double tube sheet design shell & tube heat exchanger reduces the risk of leakage.

The evaporator features a vertical rising film design. The water in the shell side of the evaporation chamber can be fully drained, guaranteeing the reliability of the water quality.

The system uses a compressor to compress secondary steam, increasing its temperature and pressure to supply heat for the subsequent evaporation of purified water. This process significantly reduces energy consumption. Two compressor types are available—magnetic levitation and high-speed direct drive—ensuring efficient and energy-saving performance across all models.

Condensed and qualified WFI enters to a buffer tank before being pumped to a WFI storage tank. Non-qualified water will be discharged appropriately.

| Item | ChP | Multi-effect distilled water machine | Vapor-compression WFI Still |

|---|---|---|---|

| Distilled water conductivity uS/cm at 25°C | <1.3 | <0.8 | 0.3 |

| Microbial limit CFU/100ml | <10 | <2 | Undetected |

| Total organic carbon TOC mg/L | <0.5 | <0.2 | <0.03 |

| Bacterial endotoxin EU/ml | <0.25 | <0.125 | <0.01 |

| Item | Multi-effect distilled water machine | Vapor-compression WFI Still |

|---|---|---|

| Industrial steam | 4-9bar | 2-4bar |

| Feeding water | 6-9bar Feed water pump required | 2-4bar |

| Cooling water | 2-3bar | No need |

| Compressed air | 5.5-8bar | 5.5-8bar |

| Industrial electricity | Three-phase five-wire 380V | Three-phase five-wire 380V |

| Model | Production Capacity(L/h) | Feeding Rate(L/h) | Steam Consumption(kg/h) | Electricity Power Consumption(kW•h) | Dimension(L x W x H in mm) | Weight(kg) | Steam Compressor |

|---|---|---|---|---|---|---|---|

| LRY1000 | 1000 | 1060 | 90 | 18.6 | 2800X1800X3100 | 2400 |

Leheng Maglev/ Direct-drive Steam Compressor |

| LRY2000 | 2000 | 2120 | 180 | 30.7 | 3100X2000X3150 | 2980 | |

| LRY3000 | 3000 | 3180 | 270 | 47 | 3350X2150X3300 | 4080 | |

| LRY4000 | 4000 | 4240 | 360 | 60 | 3600X2400X3550 | 5180 | |

| LRY5000 | 5000 | 5300 | 450 | 72 | 3850X2600X3750 | 6500 | |

| LRY10000 | 10000 | Contact us to get more details | |||||

| LRY15000 | 15000 | ||||||

| LRY20000 | 20000 | ||||||

| LRY25000 | 25000 | ||||||

| LRY30000 | 30000 | ||||||

| Customized design | Customized design | ||||||

|

Note: |

|||||||

Address : No. 558 Binhai 8th Road, Binhai Park, Economic and Technological Development Zone, Wenzhou, Zhejiang Province, China

Te : +86-0577-86906886

Fax : +86-0577-86906900

E-mail : marketing@china-yaguang.com

P.C. : 325025

Copyright © Zhejiang Yaguang Technology Co., Ltd. ALL Rights Reserveds