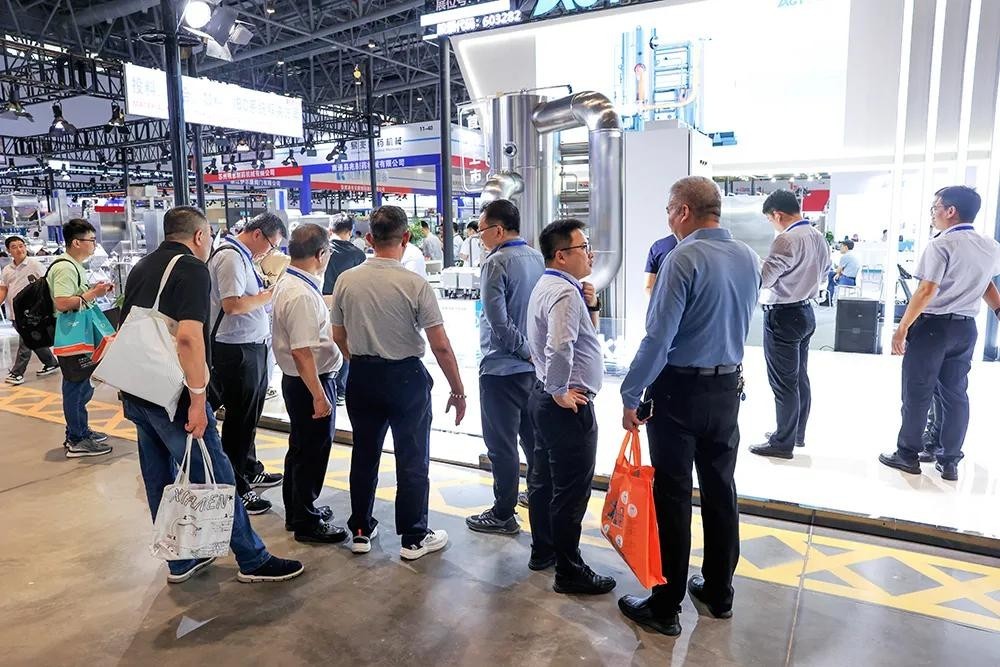

The 65th CIPM has successfully concluded, and AGT not only showcased its well-known advantageous products such as the "ANFD" Agitated Nutsche Filter Dryer, Rubber Stopper & Aluminum Cap Washing Machine, and API production line overall solution, but also showcased its groundbreaking Maglev Vapor-compression WFI Still, attracting many customers with WFI production needs to come and learn and exchange ideas.

AGT Maglev Vapor-compression WFI Still newly launched

AGT Maglev Vapor-compression WFI Still has attracted numerous customers

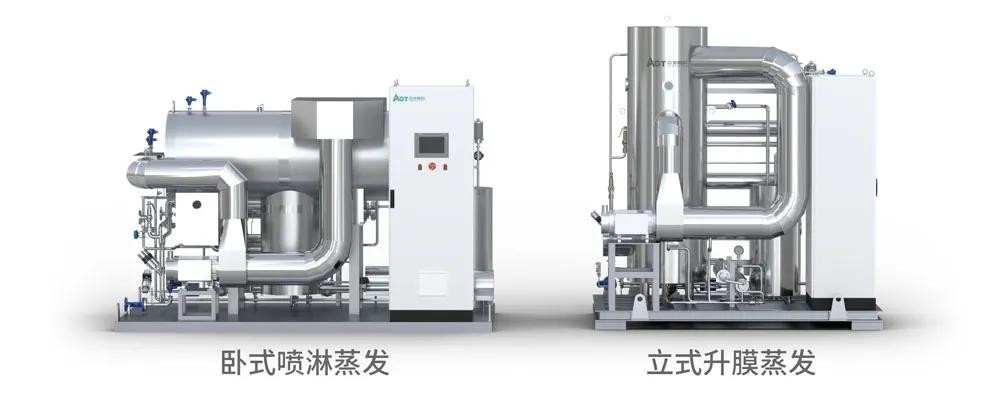

AGT Maglev Vapor-compression WFI Still has two structural forms: horizontal spraying evaporation and vertical rising film evaporation. The water production rate covers 1-100T/h, and it has the advantages of low energy consumption, good water quality, and low maintenance. All pipelines follow 3D structural design, and the preheater adopts a double tube plate structure, with inner tube plate expansion and outer tube plate welding, in compliance with cGPM and FDA requirements.

horizontal spraying evaporation & vertical rising film evaporation

01Good water quality

AGT Maglev Vapor-compression WFI Still adopts a unique structural design and uses atmospheric pressure evaporation. The evaporation temperature is low, and the risk of producing red rust is low. Compared with multi effect distilled water machines, it greatly improves the quality of the produced water.

Produced water quality:

endotoxin <0.01EU/ml

conductivity <0.3μm/cm @25℃

Unique structural design

02Equipped with LeHeng Maglev Steam Compressor

MVR steam recompression technology is the key to energy-saving of Maglev Vapor-compression WFI Still. This product is equipped with a maglev centrifugal steam compressor independently developed by AGT and its subsidiary LeHeng Energy saving. LeHeng Energy saving has been deeply involved in the field of MVR steam compressors for more than ten years, with a cumulative installed capacity of over 800 units. It has core technology research and development capabilities in steam compressor pneumatic design, rotor dynamics design, structural design, etc. At the same time, it has advanced processing and testing equipment such as Hermle five axis machining center, Zeiss three coordinate instrument, and Schenck super speed test bench to ensure the performance and reliability of compressors.

Hermle five axis machining center

Zeiss three coordinate instrument

Schenck super speed test bench

03Few repair and maintenance needs

AGT Magnetic levitation steam compressor is based on LeHeng's mature and reliable high-speed direct drive technology. Without a gearbox, it can achieve zero mechanical friction, zero lubricating oil, and zero cooling water. Not only does it reduce the risk of oil mist pollution, but it also greatly reduces the need for maintenance, which has great advantages compared to other forms of steam compressors.

If you would like to learn more about AGT Maglev Vapor-compression WFI Still, please feel free to contact us.